Unlocking the Power of S&OP for Enhanced Business Performance

- Keith Holdsworth

- Oct 29, 2025

- 4 min read

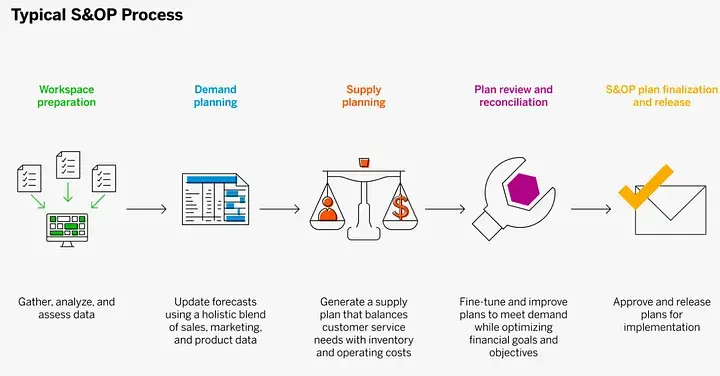

In today's rapidly changing business landscape, aligning demand, supply, and financial plans isn’t just important; it's essential for survival. A well-implemented Sales & Operations Planning (S&OP) process serves as the foundation for this alignment, allowing businesses to create a unified operating plan that boosts overall performance.

This structured, monthly process engages crucial stakeholders from Sales, Marketing, Operations, Finance, and Product Management. Their collective efforts lead to improved forecast accuracy, better inventory management, enhanced service levels, and increased profitability.

The S&OP process is more than a routine task; it’s a transformative strategic initiative. By prioritizing collaboration and data-driven decisions, companies can proactively respond to market changes, optimize resources, and achieve their business goals.

Data Gathering & Demand Forecasting

The first step in the S&OP process is data gathering and demand forecasting. This involves collecting relevant information about demand, supply, and financials to create a statistical baseline forecast. However, this baseline is just the starting point; it must be fine-tuned with insights from sales and marketing teams to better reflect market conditions.

Accurate demand forecasting is critical to effective supply chain planning. Research indicates that organizations with advanced forecasting capabilities can enhance forecast accuracy by 20% or more. By utilizing historical data and industry trends, companies can create reliable forecasts that form the foundation for subsequent steps in the S&OP process. This initial step sets the stage for collaboration across departments, ensuring everyone shares a common understanding of future demand.

Demand Review

Once the demand forecast is established, the next phase is the demand review. This involves cross-functional validation of assumptions, market dynamics, promotions, and their potential revenue impacts. The goal here is to establish a consensus demand plan that all stakeholders agree on.

During the demand review, teams engage in discussions to validate and challenge the forecast. This collaborative approach helps attribute potential risks and opportunities, aiming for a robust and realistic demand plan. For instance, suppose the marketing team anticipates a 15% spike in demand due to a planned promotional campaign. In this case, aligning this insight with production capabilities from Operations can significantly enhance the integrity of the demand plan.

Supply Review

Following the demand review, the focus shifts to the supply review. This phase examines production capabilities, inventory levels, and supplier constraints to ensure readiness to meet the forecasted demand. Scenario modeling is essential for determining how best to align supply with anticipated demand.

Effective supply planning hinges on a thorough understanding of production capacities and limits. Sophisticated organizations go beyond manufacturing planning and optimization, and consider all elements of their supply chains including the planning of transportation, network allocation, warehousing and handling capacities.

Statistics show that companies that proactively identify bottlenecks in their supply chains can reduce lead times by as much as 50%. By analysing these factors, organizations can pinpoint potential disruptions and devise strategies to mitigate them, leading to better service levels and lower holding costs.

Integrated Reconciliation

The integrated reconciliation phase is where demand and supply meet. This step involves evaluating trade-offs and updating financial implications to ensure that the plans are both attainable and balanced. Organizations need to grasp the financial impact of their decisions to make informed choices.

During this phase, teams delve into various scenarios and their potential outcomes. For example, adjusting inventory levels may improve service rates by 10%, but it could also increase carrying costs. By weighing these options, organizations can find the best path forward that not only meets customer demand but also maximizes their resources and financial outcomes.

Executive Review & Approval

The final step in the S&OP process is the executive review and approval. Senior leaders play a vital role, as they are charged with approving the integrated plan. This approval process entails making crucial decisions about production, inventory management, capital investments, and sales strategies.

Having top leadership involved ensures that the S&OP plans are aligned with the organization’s strategic vision. Their insights and endorsement drive accountability and commitment across all levels, leading to improved business outcomes.

Key Factors for Success

To ensure a successful S&OP implementation, several important factors should be considered:

Clear Ownership and Governance: Establishing ownership for each step of the S&OP process fosters accountability and efficient execution.

Defined Monthly Cycle: Regularly scheduled reviews of the S&OP process aid focus and discipline.

Reliable Data and System Integration: Timely, accurate data is crucial for effective decision-making.

Cross-Functional Collaboration: Fostering teamwork among departments creates a shared mission and vision.

By prioritizing these factors, organizations can achieve a fluid, effective S&OP process, ultimately leading to superior business performance. This list of factors also clearly demonstrates how important PEOPLE are to a successful S&OP within a company, as it is through the collaboration of functions that the best chance of success is achieved.

Final Thoughts

A mature S&OP process shifts from reactive planning to strategic, proactive decision-making. By coordinating demand, supply, and financial plans, organizations can effectively respond to market fluctuations, optimize resources, and enhance long-term business performance.

For supply chain executives, embracing the power of S&OP is not merely a best practice; it’s essential in today’s competitive environment. By investing in a solid S&OP process, organizations can unlock new efficiencies, boost profitability, and enhance customer satisfaction, setting themselves up for ongoing success.

Comments